6+ Tim Woods Lean

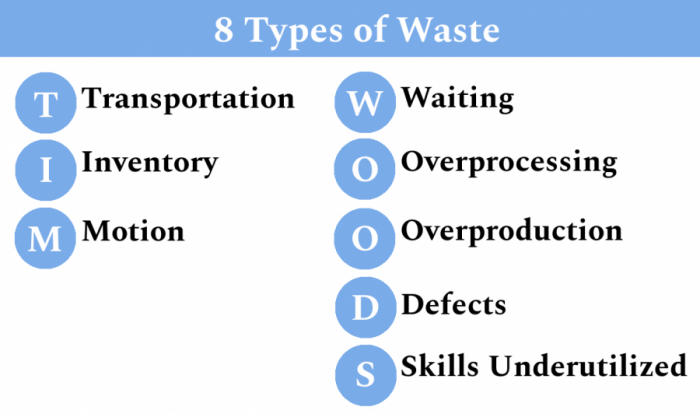

While Pete has learned the basics of Six Sigma and Lean he soon finds out that there is much more to learn. Transport Inventory Motion Waiting Overproduction Overprocessing Defects and Skills.

Business Performance Improvement Bpi

The 8 wastes of LeanStart your Lean journey with Clarity VM Consulting.

. This form provides a template with which to carry out an efficiency audit of a. Web Originally there were 7 wastes Muda defined by Taiichi Ohno the Chief Engineer at Toyota as part of the Toyota Production System TPS. Web Why are Lean and Six Sigma Important.

Web TIM WOODS is an acronym for the eight wastes that can plague a processing facility. Web Its an acronym that encapsulates the eight types of waste in Lean Six Sigma. Web Lean Six Sigma TIMWOODS 1.

Transport Waste in transportation includes the movement of people tools inventory equipment or products further than necessary. Web PowerPoint Presentation HAVE YOU SEEN TIM WOODS. In lean manufacturing waste is any cost effort or material that is.

Web Over-Processing 7. The seven wastes are. Work through our entire series on Lean waste with.

Continuing on our TIM WOODS Series is Damian White talki. Skills- The 8th Waste Identifying and Getting Rid of the Eight Wastes The 8 wastes of Lean Manufacturing are what we are attempting. Transport inventory motion waiting overproduction over-processing and defects.

Web TIMWOODS is waste - it is an acronym that provides us with a framework for finding all the wasteful steps in our processes so we can then remove them. Overprocessing Extra Processing. Web 8 Wastes of Lean checklist TIMWOODS is a simple way to audit the efficiency of your laboratory.

TIM WOODS is an acronym that represents the 8 forms of waste found in processes that should be reduced or. Web TIMWOOD is a mnemonic to remember the seven wastes in lean manufacturing. TIMWOOD stands for Transport Inventory.

Skills Underutilized Non-Utilized Talent. The 8 wastes of. Web TIM WOODS.

The 8 wastes of lean - Over-ProcessingStart your Lean journey with Clarity VM Consulting. Specifically he needs to. The DOWNTIME List of Waste.

Web TIMWOOD is a framework that Toyota developed to help identify and eliminate waste in manufacturing operations. The 8 wastes of lean - Skills Clarity Lean Visual Management 47 subscribers Subscribe 0 Share 129 views 3 years ago TIM WOODS.

Embedded Data

Embedded Data

Precisely

Youtube

Business Performance Improvement Bpi

Business Performance Improvement Bpi

Linkedin

Youtube

C Tek Lean Solutions Inc

Business Performance Improvement Bpi

Edison365

Business Performance Improvement Bpi

Edison365

Business Performance Improvement Bpi

Sweetwater

Pinterest

1